Conveyor guarding in mines

Learn about the legal requirements and best practices for guarding conveyors in mines.

Purpose

These guidelines help technical experts and workplace parties in mining operations understand the requirements in Regulation 854 – Mines and Mining Plants under theOccupational Health and Safety Act (OHSA) and may suggest best practices to prevent injury and illness to workers.

Workplace parties include employers, supervisors, contractors, joint health and safety committee members and workers.

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply and enforce these laws based on the facts they find in the workplace.

Objectives

- to provide guidance to assist in complying with legal requirements for guarding of conveyors, including preventing worker access to pinch points that are or may become accessible

- to provide information on current best practices for engineering and design to provide optimum safety for workers

Background

Conveyors are widely used in Ontario mines. Workers may be exposed to certain hazards if conveyor belts and related equipment are not properly guarded and maintained. Ontario workers have been killed or injured when they came into contact with equipment or components, such as conveyor drive belts and improperly guarded pinch points.

This guideline supports other safety policies and practices in the workplace, such as locking and tagging procedures when repairs, adjustments or other maintenance work is performed on conveyors [Reg. 854 s. 196(6)].

Legal requirements

This document discusses requirements from the following sections in the Regulation 854:

- section 196 (conveyor guarding)

- section 196.1 (emergency stopping systems)

- section 185 (counterweight guarding and energy isolation procedures)

- section 59 (1) (guarding for all openings, sumps, vessels, bins, hoppers, elevated platforms or pits, other than grease pits, which constitute a hazard)

- sections 5.1, 5.2, 5.3 (risk assessment)

Terms

Subsection 185(1) of Regulation 854 defines “machine” to include a prime mover, transmission equipment and thing.

The following terms are not defined in the regulation. The descriptions are included for general guidance purposes only. The precise context must always be considered.

- Pinch point

- A pinch point is a place where it is possible for a body part, article of clothing or an object to be caught between moving parts or between moving and stationary machine parts

- Barricade

- A barricade is any object or structure that creates a barrier or obstacle to control, block passage or force the flow of vehicular traffic in a desired direction

- Danger zone

- The zone around the machine (front, back, sides, top, and bottom) where a hazard may exist

- Energy isolating device

- A mechanical device that physically prevents the transmission or release of energy, including but not limited to, the following: manually operated electric circuit breaker; a disconnect switch; a manually operated switch by which the conductors of a circuit can be disconnected from all ungrounded supply conductors; a line valve; a block; and other devices used to block or isolate energy

- Fence

- A fence is a barrier or other upright structure that encloses an area of ground to mark a boundary, control access or protect workers

- Guard

- A device, shield, barrier, or other means used either singly or in combination, that provides effective protection to workers from hazards. As a general matter, a guard is considered secured when a tool is required for removal.

- Gate

- A gate is a type of barrier that can be used at an opening or entrance in a fence or barricade to prevent access to an operating conveyor. See section 196 (3.2) (c).

Types of conveyor guards

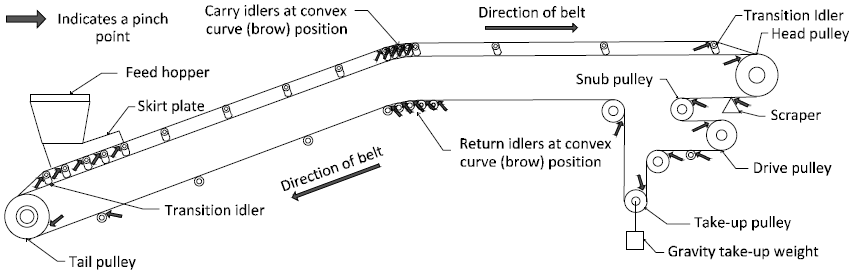

As a general matter, accessible pinch points must be guarded at the head, tail, drive, deflection and tension pulleys or if the lift of the belt is restricted, the return rollers and carry rollers [Reg. 854 s. 196 (3)]

Different types of guards include the following.

Fixed enclosure guards

A fixed enclosure guard is fastened in place (i.e., closed or attached to a fixed surface) either permanently (e.g., by welding) or by means of securing (screws, nuts, etc.), using a tool. A fixed enclosure guard prevents access to a hazardous location or other area. Where hinges are used, the guard must:

- be secured to prevent easy removal or access to the pinch point and require a tool to take it apart

- note that a key is not considered to be a tool

Interlock fail-safe barrier guard

An interlocked fail-safe barrier guard is a fixed or moveable guard attached and interlocked in such a manner that the machine tool (conveyor) will not cycle or will not continue unless the guard itself or its hinged or moveable section encloses the hazardous area and a reset function has been operated.

Adjustable barrier guard

An adjustable guard is a fixed guard that is adjustable as a whole or that incorporates adjustable parts. The adjustment to the guard remains fixed during operation and prevents access.

All guards should be installed, maintained and operated in accordance with the manufacturer’s instruction or based on competent instruction.

Equivalent protection

Guarding is not required if a conveyor’s position or construction provides equivalent protection by rendering pinch points inaccessible to workers [Reg. 854 s. 196 (3.3)]. For example, pinch points may not be accessible to workers because of a conveyor’s height or configuration.

Guarding locations

Guarding in vicinity of pulleys

Head, tail, drive, deflection and tension pulleys must be guarded at any pinch point that is or may become accessible. Other accessible pinch points in the vicinity of these pulleys should also be guarded.

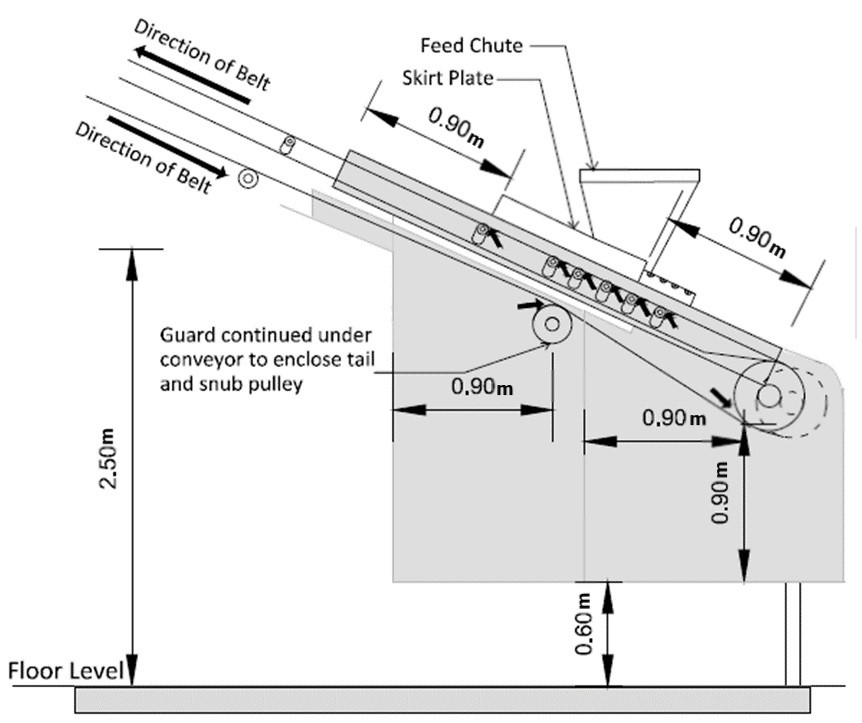

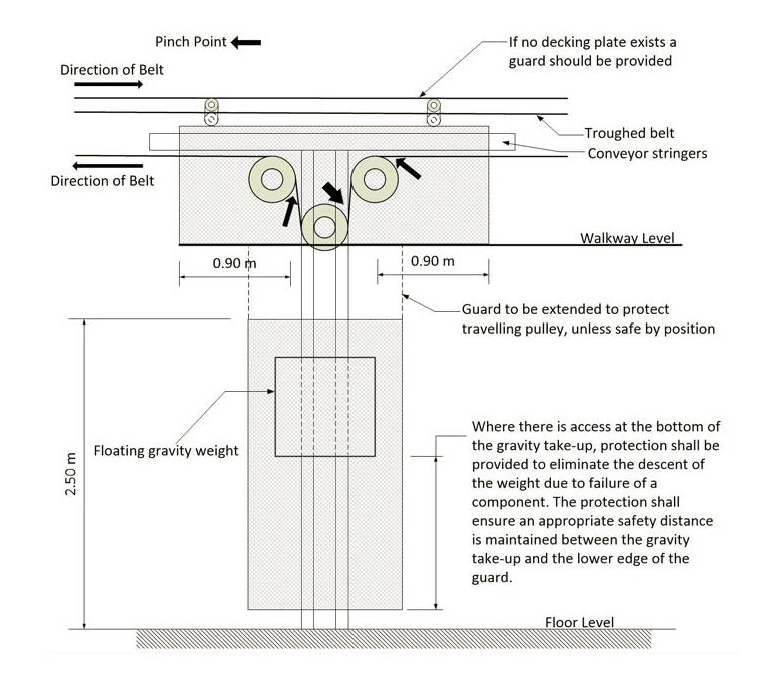

Guarding at or around take-up pulleys

A gravity take-up device is used to provide tension for a conveyor belt. Generally, a free weight is suspended on a tension pulley from deflection (bend) pulleys on the return side of the belt. This take-up travelling pulley with weight is free to lower as needed, to remove any slack as the belt is operated.

Generally, all components of a take-up device, with counter-weight system must be guarded in accessible spots. This applies to components that can move during operation as well as to return and carry rollers, if the lift of the belt is restricted. For more information, see deflection and tension pulleys [Reg. 854 s. 196 (3)] and for counterweight [Reg. 854 s. 185 (4)]. Guarding should be provided for take-up devices that operate automatically. This is to prevent access to all components of a tension carriage or balance weight.

If the bottom of a gravity take-up is accessible, guarding protection must be provided to prevent injury to a worker as a result of the weight falling due to failure of a component [Reg. 854 s. 185 (4)]. Provisions should be made for the removal or disposal of spillage in this area.

Suitably worded signs warning of stored energy should be visible at each point of access at the take-up and rope systems.

Guarding at carry and return idlers when the lift of the belt is restricted

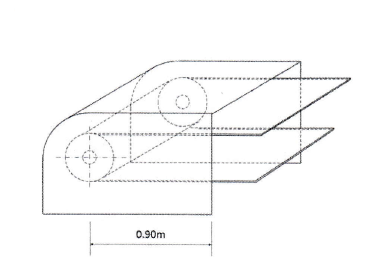

Carry (troughing) idlers are located on the carrying (top) side of the conveyor belt and are designed to make a conveyor belt curve into a cupped shape. This increases a conveyor’s carrying capacity. Return idlers or rollers are used as support on the unloaded side of the belt.

Workers must be prevented from accessing pinch points where the lift of the belt is restricted at carry and return rollers (idlers) [Reg. 854 s. 196(3)(2)].

The areas of the belt that contact either carry or return rollers and change the angle of deflection must be guarded. It is important to guard at a convex curve due to the high pressures generated between the belt and rollers. Other areas in which the lift of the belt may be restricted include structures sitting on top of the belt, such as hoppers etc.

Guarding at hoppers and chutes

All openings to hoppers and chutes that constitute a hazard must be suitably guarded [Reg. 854 s. 59 (1)]. Hoppers and chutes should be provided with access or openings so any needed cleaning or inspection may be done outside the hopper or chute, as much as possible.

Guarding at loading, unloading and discharge points

Guards should be installed to prevent injury whenever a worker has access to loading, unloading, workstation, transfer or discharge point.

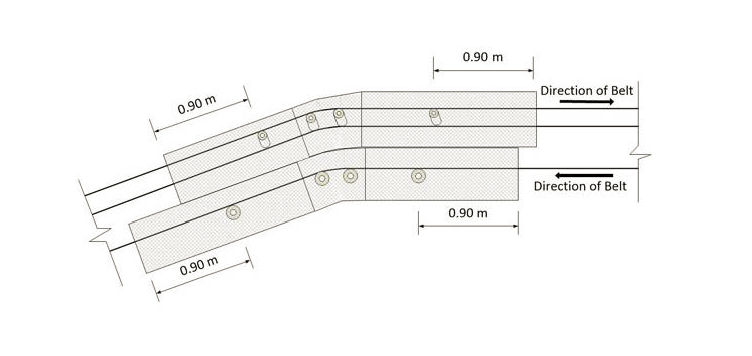

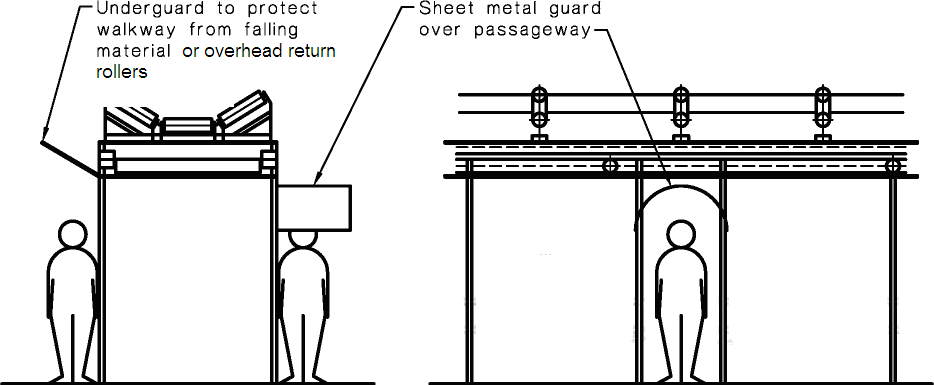

Guarding at crossovers and underpasses

Crossovers and underpasses should be provided at appropriate locations when access to either side of a conveyor is required. This may include crossovers or underpasses at the head and tail ends, drive and other transfer points along the conveyor.

Guards must be provided under conveyors that pass over a worker, or if there is a risk of falling materials or parts endangering a worker [Reg. 854 s. 196 (4)]. Consideration should be given to the height, mass and speed of the material being conveyed. The employer should designate appropriate crossovers and underpasses in consultation with the workplaces’ Joint Health and Safety Committee (JHSC) or Health and Safety Representative, if any.

Summary of pinch points requiring guarding:

- head pulley

- tail pulley

- drive pulleys

- deflection pulleys

- tension pulleys

- return rollers where the lift of the belt is restricted

- carry rollers or troughing rollers where the lift of the belt is restricted

Construction and strength of guarding material

Typically, guards should be constructed of sheet metal, mesh or equivalent material. Guards should be sufficiently rigid, with openings that are sized and braced to ensure that safe distances are maintained in case a worker inadvertently or unintentionally makes contact with a guard.

As a guide, sheet metal guards should be at least 1.5mm thick. Mesh guards should consist of at least 1.5mm wire gauge or 3mm wire gauge for a 50mm square mesh section. If alternative guarding material (other than stated above) is used, it should at least resist a force of;

- 450N (100lbs) at a point on the guard applied over a 50mm by 50mm square area

- 220N (50lbs) applied to selected points to test the strength of a guard that can be climbed on or rested upon when a simultaneous mass of 90kg (200lbs) is placed on the guard.

The required clearances from the danger zone should be maintained when a force of 450N (100lbs) is applied at points on a guard over a square area of 50mm by 50mm.

Non-metallic materials may have strength and flammability issues, fire/chemical damage or deterioration caused by long-term UV exposure.

Repairs, adjustment and maintenance of conveyors

Generally, a conveyor must be stopped, de-energized, locked and tagged out when a conveyor is undergoing repairs, adjustments or maintenance. If removal of guards is required, they must be replaced before restarting the conveyor.

If a conveyor must be operated during such work, effective precautions need to be taken to prevent worker injury from moving parts [Reg. 854 s. 196(6)].

Precautions may include, but are not limited to, extending grease lines to outside the guards. As well, the conveyor belt adjusters can be moved outside the guards so guards do not have to be removed while maintenance is being carried out to prevent worker contact from those moving parts.

Inspection/maintenance doors in fixed guards

Inspection doors may be provided on fixed guards subject to certain conditions. For example, incorporating an inspection door must not expose a worker to pinch points or moving parts or material. Also, an inspection door must not be used when the conveyor is running unless conditions are met in Reg. 854 s. 196(6).

Fences, barricades and gates

Fences, barricades and gates can be used to prevent worker access to pinch points if it is impracticable to guard a pinch point required by Reg. 854 s. 196(3.1) These alternative options are allowed under Reg. 854 s 196(3.2).

Fences and barricades can be used to isolate a general area where one or more pinch points are located. The difference between a fence and a barricade is that a fence is typically used to enclose, contain or separate a conveyor or part of a conveyor from the surrounding area. A barricade is used to close, block or otherwise prevent access to an area where a conveyor is being operated.

Fencing needs to completely enclose a dangerous area and prevent access to pinch points. The fence needs to be of sufficient strength and construction, so workers have no access to pinch points if they reach under, over or through a fence.

A barricade is used to isolate a general area or otherwise prevent access into the area by virtue of its physical dimensions and it distance from the hazards. The barricade needs to prevent access based on the type of traffic that needs to be controlled. For example, a cement block may be used to prevent vehicular traffic, but not pedestrian traffic.

Where a gate is used, it must be equipped with an interlocking device with a manual reset switch that will render a conveyor inoperable until the reset has been activated [O. Reg. 854 s. 196(3.2)(c)]. This safety feature does not take the place of the lock and tag requirements described in Reg. 854 s. but may be used in conjunction with those requirements. Not every fence or barricade needs to have a gate. However, those that do must meet the requirements of Reg. 854 s. 196(3.2)(c) and 185(7) to provide workers with a controlled access point.

Fences, barricades and gates all serve the same purpose to prevent access to a dangerous area when guarding is not practicable.

Emergency stop pull cord or other emergency stopping system

An Emergency Stopping System (ESS) is a manual or automatic operated system designed to stop a conveyor system in an emergency. Examples of ESS include pullcords and e-stops. The purpose of pull cords and other ESS’ are to stop a conveyor in case of an emergency. They are not intended as a substitute for a guard, fence or barricade.

An ESS must be resettable. The reset should be available only at the location where the emergency stop command is initiated. The ESS command must be manually reset before the conveyor can resume operation. A separate action is needed to then start the conveyor. This could include using a start button, switch, control room activation etc.

Specific precautions should be followed when pullcords are used. The system should be designed and arranged to operate the switching device to generate the emergency stop signal when:

- the pullcord is pulled in any direction

- a perpendicular pulling force of less than 200N (45lbs) is applied to the pullcord and

- the perpendicular deflection of the pullcord is less than 400mm (15 ¾”) occurs

In addition, a pullcord should be able to withstand, without breaking, a tension force 10 times greater than is necessary to generate the emergency stop signal.

A visual indicator should be installed to show which device was activated when a long pullcord or more than one switching device is needed.

An ESS is required at any pinch point on a conveyor that is not set out in Reg. 854 s. 196(3). This applies only if the conveyor is accessible to a worker. Such pinch points may be located at carry or return rollers where the lift of the belt is not restricted. The ESS must be readily accessible by workers at each of these pinch points.

If the conveyor is accessible to a worker, the ESS must also be available at other locations along the conveyor to ensure the system is always within a worker’s easy reach.

The location of an ESS must be determined in consultation with a workplace’s Joint Health and Safety Committee (JHSC) or Health and Safety Representative (HSR), if a conveyor is inaccessible to workers [Reg. 854 s. 196.1(3)].

Equipment incorporating conveyors

Belted conveyor systems in crushing and screening plants must comply with Reg. 854 s. 196 and 196.1. Other moving equipment parts in crushing screening plants must be guarded [Reg. 854 s. 185]

Training

Employers must:

- establish and maintain the required training programs and train each worker in the required modules as may be applicable ( see sections 11 - 11.2.3)

- ensure all workers and supervisors receive instruction, training and supervision to protect their health and safety, including that related to any conveyor that they may operate or work in proximity to [OHSA clause 25(2)(a)].

- maintain documentation and/or records of relevant training.

Consultation

The Ministry of Labour, Training and Skills Development expects an employer to meaningfully engage with the Joint Health and Safety Committee or Health and Safety Representative, if the Occupational Health and Safety Act or its regulations require another party (such as the JHSC or HSR) to be consulted on an action. This interaction must include dialogue, discussion and providing all relevant information.

The JHSC or HSR must be given a genuine opportunity to comment. Those comments should be received and considered in good faith. This includes taking into account any feedback and responses from the JHSC or HSR before taking action such as implementing a plan or program etc. It also includes responding to any recommendations arising from consultation.

An employer does not meet the requirements for consultation if he or she informs the JHSC or HSR of a planned action.

Available standards and guidelines

- CAN/CSA Z432-16, Safeguarding of Machinery

- Australian Standard 2015 AS/NZS 4024.3610 - Conveyors - General requirements

- Australian Standard 2015 AS/NZS 4024.3611 - Conveyors - Belt conveyors for bulk material handling

- British Standard BS EN 620:2002, Continuous Handling Equipment and Systems-Safety and EMC Requirements for Fixed Belt Materials for Bulk Material

- CAN/CSA Z1002-12, Risk Management: Guideline for Decision Makers

- Workplace Safety North, Guarding Equipment – Belt Conveyor Guarding

- U. S. Department of Labor, Mine Safety and Health Administration, Guide to Equipment Guarding 2004

- Workplace Safety and Prevention Services, A User’s Guide to Conveyor Belt Safety, Protection from the Danger Zones