Mobile compacting equipment safety guideline

Employers with solid waste mobile equipment can use this guideline to help them meet their point-of-operation guarding obligations under the Occupational Health and Safety Act.

Introduction

The focus of this guideline is point-of-operation guarding. This guideline applies to all types of mobile compacting equipment, including:

- front-loading compacting equipment

- rear-loading compacting equipment

- side-loading compacting equipment

- container lifting equipment

- multi-compartment recycling vehicles

- combination collection equipment

There are many other hazards that you must consider in order to ensure worker health and safety while operating mobile compacting equipment. Some of the other important issues (not covered in this guideline) include:

- personal protective equipment

- hygiene issues

- ergonomics

- traffic control

- high visibility safety apparel

- lockout

- blocking

- fall protection

This guideline provides general assistance where potential hazards are encountered. It is not intended to provide an all-inclusive list of hazards and controls.

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations, and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.

More information about the duties of employers and other persons can be found in the Guide to the OHSA.

If you need more information about safety requirements, please contact the Ministry of Labour Health & Safety Contact Centre at

How to use this guideline

To help in complying with the OHSA, employers may use:

- the general guarding principles set out in section 1

- the specific guarding examples set out in section 2

- the principles set out in in Canadian Standards Association (CSA) Z432 Safeguarding of Machinery

- a combination of any of the above, depending on the particular circumstances of the workplace

Section 1: General principles of guarding

Overview

The guarding principles presented in this guideline are based on principles set out in Canadian Standards Association (CSA) Z432 Safeguarding of Machinery.

In simple terms, the general principle of guarding is to prevent worker injury and prevent worker access to the hazard.

This can be achieved by:

- preventing worker access to the pinch point

- preventing movement of the equipment while a worker is present

- removing the worker from the point of operation

In situations where more than one worker is present, consider how each worker is protected from the hazard.

Pinch points

Injuries can occur when workers are exposed to a hazard. For mobile compacting equipment, there is a hazard at the point-of-operation pinch point.

Pinch points occur where a part of the body could be caught between moving parts and/or moving and stationary parts of equipment. For example, when a packer panel meets the vehicle body or a container meets the vehicle body.

Guarding methods

Some guarding methods are more robust and most commonly found on mobile compacting equipment.

There are three common methods of preventing worker access to the hazard.

- sustained pressure control

- interlocking gate

- guarding by distance

Using the principles outlined in this section will help employers achieve compliance with OHSA requirements. These principles allow employers flexibility in determining their own guarding solutions to their specific situations.

Method 1: Sustained pressure control

The most common and robust guarding method in the industry today is a hold-to-run or sustained pressure control solution.

Sustained pressure control is a device which the operator must hold for movement to occur. When a sustained pressure control is released, movement stops.

How it works

If the control is near the hazard, both hands must be used. If the control is further away and the operator cannot reach the hazard, only one hand is required to operate the sustained pressure control.

The control must be located so that a worker cannot access the hazard with any body part, including their foot. However, the worker must have full view of the pinch point so the movement can be stopped if another worker or member of the public approaches the hazard.

Considerations

Sustained pressure control only protects the worker holding the device. When more than one worker requires protection, more than one sustained pressure control must be present.

When selecting a style of control for use on a vehicle, you should consider:

- ergonomics

- use while wearing gloves

- environmental conditions

- whether the safety features could be bypassed by a worker

Method 2: Interlocking guard

An interlocking guard is a movable guard associated with an interlocking device.

The hazardous functions "covered" by the guard cannot operate until the guard is closed, and the closure of the guard does not initiate the operation of the hazardous functions by itself.

If the guard is opened while hazardous functions are operating, the hazardous function automatically stops. The switches are tamper-resistant.

An interlocking gate protects all workers in the vicinity. Interlocked guard controls may be:

- electrical

- mechanical

- hydraulic

- pneumatic

For more information on the design of interlocked guards or other safeguarding designs please refer to CSA Z432 Safeguarding of Machinery.

Considerations

An interlocking gate must be large enough so that a worker can't reach around it to access the pinch point. Routine inspection and testing must be carried out at a frequency appropriate to ensuring the continued integrity of all safety related control functions.

Method 3: Guarding by distance

Where a worker cannot reach the hazard, the hazard is considered guarded by distance. For example:

- a large chute where the moving equipment is at the far end, out of reach of the worker

- equipment that can only be operated by the worker while in the driver's compartment for one-worker operations

Other guarding methods

There are many other methods of preventing worker access to the hazard.

Fixed access or barrier guard

A fixed guard prevents worker access because of its size and location away from the hazard. It may be constructed of any material that is strong and durable. It is permanently attached or padlocked in place.

Any openings in the guard must be small enough to prevent a worker's hands or other body parts from reaching the hazard.

For barriers with openings, refer to the chart in CSA Z432 Safeguarding of machinery to determine the minimum distance they must be from the hazard.

Safeguarding device

Any mechanical attachment or device, other than a guard, that:

- detects and prevents access to a point of operation hazard during the hazardous motion of the equipment

- prevents hazardous motion of the equipment during access to the point of operation hazard

For example:

- constant pressure switches, which force the worker away from the hazard

- worker detection devices (presence sensing devices), such as light curtains and safety mats, which detect the presence of a worker and stop the hazardous motion

Combination guarding

On some trucks, more than one guarding solution may be required to operate safely and efficiently. For example, a truck with a moveable guard may be the most convenient when the guard can be closed, but a sustained pressure control may need to be periodically used for large items which block the closing of the gate.

Section 2: Guarding examples for different types of equipment

This section contains specific guarding examples to help in complying with the OHSA. Not all possible guarding situations may be represented, as technology continues to evolve in the industry. Combining several operations in one vehicle may introduce additional hazards not covered by the specific equipment sections of this guideline. For such multi-functional vehicles or any vehicle not identified in this guideline, check out the general guarding principles set out in section 1.

If you are trying to comply with the OHSA and choose to follow the examples in this section, the equipment needs to comply with ANSI Z245.1 for Mobile Wastes and Recyclable Materials Collection, Transportation, and Compaction Equipment plus any additional requirements listed in the examples on this page. To make sure you are compliant, refer to the OHSA and applicable regulations.

Front-loading compacting equipment

These vehicles are used to collect waste and recyclable materials contained in bins. The front forks mechanically lift the bins and dump materials into an opening on the top of the vehicle.

Using front-loading compacting equipment that meets ANSI Z245.1 for Mobile Wastes and Recyclable Materials Collection, Transportation, and Compaction Equipment would be a reasonable precaution to take to protect workers.

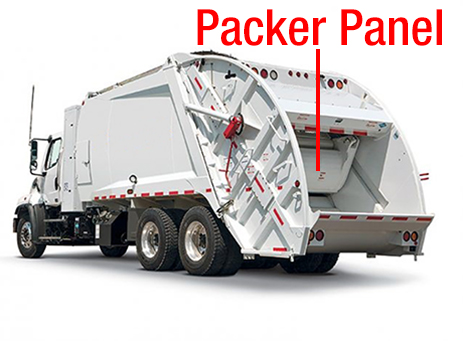

Rear-loading compacting equipment

These vehicles are used to collect both waste and recyclable materials. Materials are placed manually into one or more openings in the rear of the vehicle.

Note: Single stream (Figure 2) and split stream (Figure 3) rear loading equipment have the same types of hazards and safety controls – the only difference is the number of hopper openings. Figure 3 also shows container lifting equipment, which is addressed in the container lifting equipment section.

Guarding example: Moveable guard

If a moveable guard is used to prevent worker access to the point-of-operation pinch point during the packing cycle, the following must be met:

- the movable guard must be interlocked so that it has to be in place before the packer panel can move within 150 mm (six inches) of the pinch point

- the movable guard must be designed so that it is not hazardous in itself and should be designed so that the hazard from projectiles during the packing cycle is eliminated

For guard interlocking see Section 1.

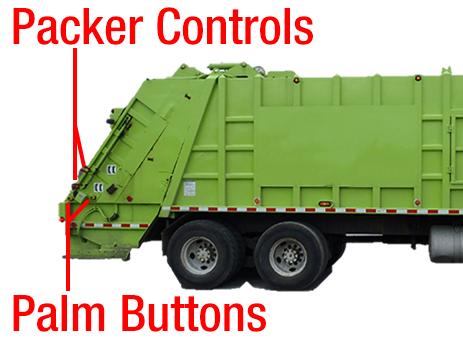

Guarding example: Controls

If controls are used to prevent worker access to the hazard, all of the following has to be in place:

- the control provides an interrupted cycle, where:

- actuation of the control must cause the packer panel to stop not less than 150 mm (six inches) or more than 406 mm (sixteen inches) from any pinch point

- re-actuation of the control by a subsequent motion of the worker is required to complete the packing cycle

- actuation of the control to complete the packing cycle must be by sustained manual pressure

- the control must be located so that the worker actuating the control:

- cannot reach any point-of-operation pinch point

- has a clear view of the point-of-operation

Protecting additional workers

If controls are used to prevent access to the hazard by additional workers, all of the following also have to be in place:

- an additional set of sustained manual pressure controls for each additional worker (including a trainer) must be provided

- the actuation of the controls must have to take place concurrently in order to complete the packing cycle

- the controls must be located so that a single worker cannot operate more than one set of controls

- all controls should be located on the side of the vehicle opposite the normal traffic side

Screen materials

A screen creates a physical barrier between the operator using the controls and the crusher panel.

Figure 4: Expanded metal section at the rear of a rear-loading truck

- Packer controls

- Provision for "clear view" and preventing worker from reaching the point-of-operation

- Sustained manual pressure control

The expanded metal section at the rear of the rear-loading truck shown in Figure 4 allows a clear view point-of-operation; as well, it prevents the worker from reaching the point-of-operation pinch point with their foot when standing on the riding step while operating the controls.

The use of other screen materials may be acceptable if they allow a clear view and are maintained.

Winch, reeving and hydraulic dumping systems

Controls may be used to protect workers who use rear-loading compacting equipment with winch, reeving and hydraulic dumping systems.

Winch systems, reeving systems and hydraulic dumping systems which meet ANSI Z245.1 for Mobile Wastes and Recyclable Materials Collection, Transportation, and Compaction Equipment would be a reasonable precaution to take to protect workers.

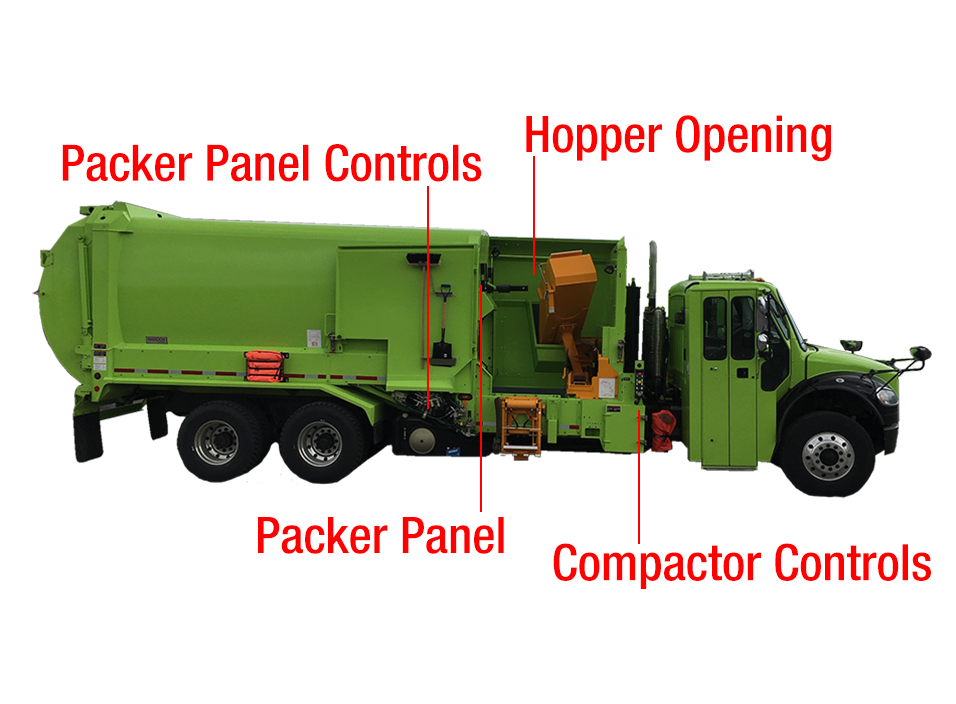

Side-loading compacting equipment

These vehicles are used to collect both waste and recyclable materials. Materials are placed manually into an opening in the side of the vehicle.

Note: Figure 6 also shows container lifting equipment, which is addressed in another section.

Guarding example: Moveable guard

If a moveable guard is to be used to prevent worker access to the point-of-operation pinch point of the packer panel mechanism, the following must be met:

- the movable guard must be interlocked so that it is in place before the packer panel cycle can be started

- the movable guard must be designed so that it is not hazardous in itself and so that the hazard from projectiles during the packing cycle is eliminated

For guard interlocking see Section 1.

The access door on the driver's side of the truck must be interlocked with the crusher panel or the door must be padlocked closed.

Guarding example: Controls

If controls are to be used to prevent worker access to the hazard, all of the following have to be in place:

- actuation of the control for the full packer panel cycle must be by sustained manual pressure

- the control must be located so that the worker actuating the control:

- cannot reach any point-of-operation pinch point

- has a clear view of the point-of operation

- the controls must be located on the side of the vehicle used for loading

If controls are to be used to prevent access to the hazard by additional workers, all of the following have to also be in place:

- an additional set of sustained manual pressure controls for each additional worker must be provided

- the actuation of the controls must take place concurrently for the full packer panel cycle

- the controls must be located so that a worker cannot operate more than one set of controls

Considerations

If an additional worker is performing a "restricted driving-only" function as a result of "modified work" provisions, additional manual pressure controls would not be required. Operational policies have to be in place which prohibit the driver from operating the packer panel controls.

Loading platforms on side-loading compacting equipment

Any loading platform on side-loading compacting equipment must be equipped with a reliably functioning pressure-sensitive protective device, or equivalent. The pressure-sensitive protective device must stop the compactor's ram movement when a worker steps onto the loading platform. The compactor ram interrupt cycle must have a manual reset function.

Side-loading compacting equipment: Type II (torpedo design)

These vehicles are side-loading, with container-lifting mechanisms that receive, compact, transport, and unload wastes or recyclable materials.

Guarding example: Moveable guard

If a moveable guard is used to prevent worker access to the point-of-operation pinch point of the packer panel, the following must be met:

- the movable guard must be interlocked so that it needs to be in place before the compacting cycle can be started

- the movable guard must be designed so that it is not hazardous in itself and should be designed so that the hazard from projectiles during the packing cycle is eliminated

For guard interlocking see Section 1.

Guarding example: Controls

If controls are to be used to prevent worker access to the hazard, all of the following have to be in place:

- actuation of the control for the packer panel must be by sustained manual pressure

- the control must be located so that the worker actuating the control:

- cannot reach any point-of-operation pinch point

- has a clear view of the point-of-operation

If controls are to be used to prevent access to the hazard by additional workers, all of the following must also be in place:

- an additional set of sustained manual pressure controls for each additional worker (including a trainer) must be provided

- the actuation of the controls must take place concurrently for the full compacting cycle

- the controls must be located so that a worker cannot operate more than one set of controls

Loading platforms on type II side-loading compacting equipment

Any loading platform on type II side-loading compacting equipment must be equipped with a reliably functioning pressure-sensitive protective device, or equivalent. The pressure-sensitive protective device must stop the compactor's ram movement when a worker steps onto the loading platform. The compactor ram interrupt cycle must have a manual reset function.

Container lifting equipment

These vehicles are used to collect both waste and recyclable materials. Semi or fully automated systems mechanically lift and dump containers of material into a rear or side opening of a vehicle, or into a bin at the front of the vehicle.

Guarding example: Controls

Using sustained pressure controls that meet ANSI Z245.1 for Mobile Wastes and Recyclable Materials Collection, Transportation, and Compaction Equipment would be a reasonable precaution for the safety of workers.

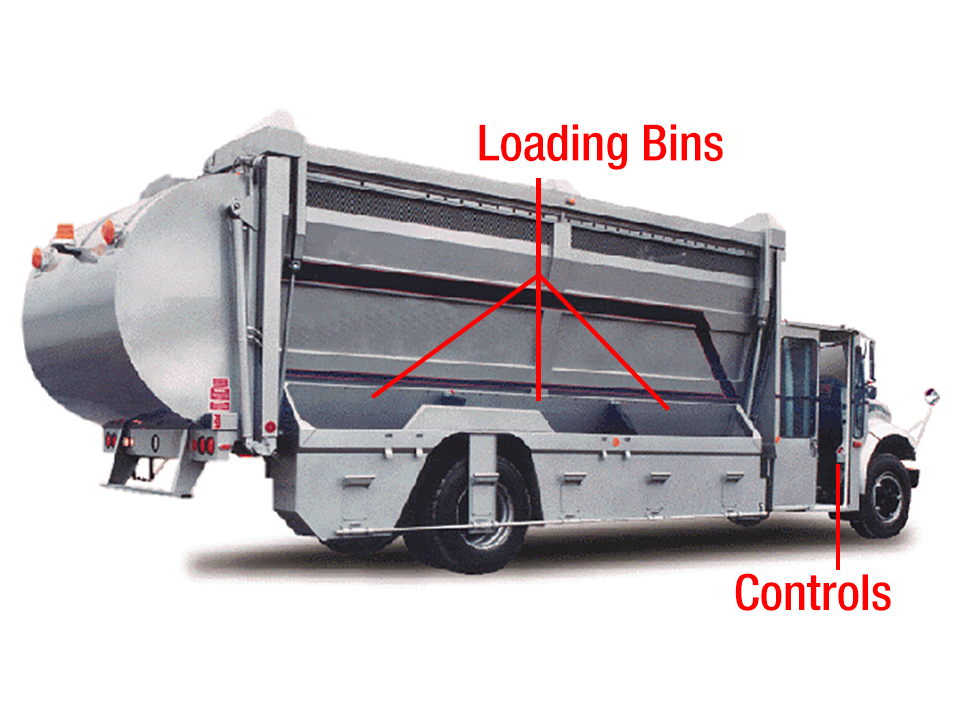

Multi-compartment recycling vehicle

These vehicles are used to collect and separate recyclable materials. Materials are separated into multiple hoppers on the side of the vehicle and then mechanically lifted and dumped into compartments on the top of the vehicle.

Figure 10: Multi-compartment recycling vehicle

- Loading bins

- Controls for "lifting-dumping-return" cycle are located in the vehicle cab (operated from outside the cab)

Guarding example: Controls

Using sustained pressure controls which meet ANSI Z245.1 Mobile Wastes And Recyclable Materials Collection, Transportation, And Compaction Equipment would be a reasonable precaution to take to protect workers.

Terminology

Terminology on this page and from ANSI Z245.1 Mobile Wastes And Recyclable Materials Collection, Transportation, And Compaction Equipment is used throughout this guideline.

- Clear view

- The operator is able to see the complete area of the point-of-operation. A clear view ensures the operator can stop the packer panel if a worker or other person is within easy reach of the pinch point.

- Hopper opening

- The opening on the body of the truck where wastes or recyclable materials are loaded

- Interlocking device (interlock)

- A mechanical, electrical, hydraulic, pneumatic or other type of device, the purpose of which is to prevent the operation of machine elements and to stop the machine if opened under specific conditions.

- Pinch point

- A point at which it is possible for a part of the body to be caught between:

- moving parts

- moving and stationary parts of equipment

- material and moving parts of equipment

- Point-of-operation hazards

- These hazards include:

- the pinch point created when the packer panel closes

- projectiles during packing

- Sustained pressure control

- The control operates moving parts and permits movement only as long as the control is held in a set position, with continual pressure from one or both hands of a worker. When the control is released, operation stops.

Appendix A: Accessing upper truck sections

Worker access onto upper truck sections while trucks are out on the road should only be permitted for emergency maintenance, service and repair work, but not for operational purposes.

Appropriate safety measures to protect workers who access upper truck sections include:

- written procedures, which are enforced

- lockout procedures to protect the worker from moving parts

- blocking of any elevated components

- blocking or chocking of wheels

- appropriate fall protection equipment, based on a hazard assessment of the work to be done on the truck

- worker training on safely accessing upper truck sections