Access and fall protection in window cleaning

Learn about industry best practices and the access and fall protection requirements under the Occupational Health and Safety Act and Regulation 859: Window Cleaning.

Overview

This guidance document sets out some of the workplace party duties under the Ontario Occupational Health and Safety Act (OHSA), some of the access and fall protection requirements outlined in Regulation 859: Window Cleaning and some industry best practices pertaining to the use of:

- boatswain’s chairs

- suspended work platform systems

- rope access

This resource is intended to assist:

- design engineers

- building owners

- employers

- supervisors

- workers

It covers some general areas of the regulation as well as key technical areas including:

- Ministry of Labour, Training and Skills Development (MLTSD) expectations and recommendations for practices that may not be specifically addressed in Regulation 859

- the Canadian Standards Association (CSA) standards and other standards, including industry codes of practices

- in many instances, the standards have been included to provide guidance for workplace parties

Workplace parties must ensure that they comply with the requirements of the Occupational Health and Safety Act (OHSA), Regulation 859: Window Cleaning, and the Building Code including standard CAN/CSA-Z91 that applies to external anchor systems. Where there may be conflicts between regulatory requirements and recommended standards in this guidance, then regulatory requirements prevail.

The OHSA, together with Regulation 859, outlines the legal requirements for engineers, building owners, employers, supervisors and workers in the window cleaning industry. Owners, employers, supervisors and workers have responsibilities under the OHSA and its regulations and are required to be familiar with and comply with the legislation and its regulations. For information about the OHSA, refer to the Guide to the Occupational Health and Safety Act.

Note that the term “employer” under the OHSA includes:

- a contractor or subcontractor who performs work or supplies services

- a contractor or subcontractor who undertakes with an owner, constructor, contractor, subcontractor to perform work or supply services

This guidance document does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.

This guidance document references the following sources where applicable:

- The Ontario Occupational Health and Safety Act (OHSA, or “the Act”)

- Regulation 859: Window Cleaning

- CAN/CSA Standard Z91-17 “Health and Safety Code for Suspended Equipment Operations”

- CAN/CSA Standard Z271-10 “Safety Code for Suspended Platforms

Notification requirements

Notice of window cleaning work

Before any worker begins window cleaning at a building where a suspended scaffold, boatswain's chair or similar single-point suspension equipment is used, every employer, contractor and sub-contractor who proposes to carry out window cleaning at the building shall give notice of the proposed window cleaning by telephone to an inspector in the office of the Ministry of Labour, Training and Skills Development (MLTSD) that is nearest to the location where the work is taking place [Regulation 859, section 7(1)].

Public protection

If practicable, a sufficient number of signs stating “danger – work overhead” in legible letters must be posted in prominent locations to warn pedestrians that window cleaning is being carried out overhead [Regulation 859, section 12].

Worker protection

Barriers, warning signs or other safeguards that are used to protect workers must be used where vehicular or pedestrian traffic may endanger the safety of any worker, disturb the worker’s safety lines or support lines (for example, restricted public access to the support system area) [Regulation 859, section 13]. The equipment should be stored in a secured position when not in use.

Electrical hazards

Electrical equipment, power lines and insulating materials shall be suitable for use and be installed, maintained, modified and operated so they do not present a hazard to a worker [Regulation 859, section 32].

The employer should ensure electrical panels on the roof are locked out and tagged to prevent unauthorized worker access to exposed energized parts. In addition, subject to the exceptions stated in subsection 35(2) of Regulation 859, no object or piece of equipment shall be closer than the distance specified in subsection 35(1) to an energized outdoor overhead electrical conductor.

Accessing work at heights and fall protection

Suspended scaffolds

All suspended scaffolds that are designed to gain access to exterior and interior surfaces of buildings and other structures must comply with the OHSA and Reg 859, including:

- testing

- inspection

- maintenance of permanently installed suspended scaffolds [Regulation 859 section 41]

The fall arrest body harness or lanyard may be attached to suspended scaffold if the suspended scaffold has at least two independent means of support or suspension and is designed, constructed and maintained so that the failure of one means of support or suspension will not upset the scaffold [Regulation 859, subsection 10(4)].

Every primary suspension line and lifeline used in connection with a suspended scaffold shall be rigged so that each line hangs vertically from the roof or access level to the ground or level of egress of a worker using the line and shall be protected from abrasion [Regulation 859, section 27].

Stabilization of suspended scaffolds as per CAN/CSA Z271-10

Stabilization of suspended scaffolds as per the CSA standard is a requirement for window cleaning operations taking place on a construction project (as per Ontario Regulation 213/91). It is also a recommended best practice for window cleaning in general, which makes using suspended equipment safer.

Stabilization of suspended scaffolds under 45 metres (150 feet)

This section addresses lateral movement of the suspended scaffold. Restraint of a suspended platform to the exterior face of a building or structure at suspension heights from 15 metres to 45 metres should be provided by angulated roping or by a purpose-built stabilization system [clauses 9.5.2, 9.5.1.2, 9.5.1.3 of CAN/CSA Z271-10].

Stabilization of suspended scaffolds over 45 metres

The exterior face of a building or structure should have a positive means of restraining the suspended scaffold to the building or structure when the suspension height exceeds 45 metres [clause 9.5.1.1 of CAN/CSA Z271].

Boatswain's chair

A boatswain's chair shall not be used where the descent exceeds 90 metres [Regulation 859, section 28].

Employers must prohibit mid-air transfers from one boatswain's chair to another. Access to a boatswain’s chair, a suspended scaffold, or similar single-point suspension equipment must be directly from the floor or roof where the equipment is adjacent to, or from ground level where the suspension equipment is at ground level [Regulation 859, section 14].

Access and egress

Every worker who is either on or is in the process of getting on or off a suspended scaffold or a boatswain's chair or similar single-point suspension equipment shall be protected by a fall arrest system [Regulation 859, section 31].

Workers must be provided with safe access to parapets over 1.07 metres in height and fall protection if over 3 metres [clause 9.3.2 of CAN/CSA Z271.10].

Fall arrest system

If a worker who is not working from a ladder is exposed to the hazard of falling more than 3 metres, the worker shall use a fall arrest system that is adequately secured to a fixed support and arranged so that the worker cannot fall freely for a vertical distance of more than 1.5 metres [Regulation 859, subsection 10(1)]. The fixed support shall be able to resist all arrest forces when a worker falls [Regulation 859, subsection 10(2)].

The fall arrest system must do both of the following:

- arrest any fall by the worker without applying a peak force to the worker greater than 8 Kilonewtons (kN) [Regulation 859, clause 10(3)(a)]

- permit the worker to remain suspended safely in it for a period of at least 30 minutes [Regulation 859, clause 10(3)(b)]

All fall arrest components should be compatible and Canadian Standards Association (CSA) certified.

Anchor points

Every owner of a building where a suspended scaffold, boatswain's chair or similar single-point suspension equipment is to be used for window cleaning or where sill work is done, must do all of the following, among other things:

- ensure that any faulty anchor point is repaired before being used

- ensure that any anchor point is suitable for use for window cleaning and sill work before being used

- keep a record of the inspections of any anchor points, (including davit bases, monorail systems, stabilizer systems, rope stops) and permanently-installed suspended scaffold in a log book

- maintain and retain the log book as long as the anchor points and suspended scaffold equipment are used

- ensure that the date of inspection and name and signature of the person making the inspection is recorded

- record any modifications or repairs made to an anchor point or a suspended scaffold, including the date they are made and the name and signature of the person making the modifications or repairs [Regulation 859, section 41]

Strength requirements for anchor points

The support capability of an anchor point shall exceed the total breaking strength of all support lines attached to it [Regulation 859, subsection 29(2)].

It is recommended that anchor points for vertical lifelines, equipment tieback and direct attachment of primary lines for suspended equipment are both:

- designed to resist the application of a force of 22.2 kN (5000 lbf) in any direction without fracture of any component or pullout, or both from the anchorage [clause 9.4.3(a) of CAN/CSA Z271-10]

- able resist a test loading of 11.1 kN without permanent deformation of any component when subjected to test loading in the direction(s) that generate the most critical effect on the anchorage system with respect to stability and strength [clause 9.4.3(b) of CAN/CSA Z271-10]

Note: the above tests should be witnessed and certified by a professional engineer.

Adhesive anchor points

Adhesive anchor installations should follow all of the following recommendations:

- incorporate a minimum of three adhesive inserts per anchor

- only use inserts that are made of stainless material

- be designed by a professional engineer

- be installed under the direction of a professional engineer

Systems incorporating adhesive expansion fasteners should also have 100% of the anchor points load tested at intervals not exceeding five years [clause 11.9 of CAN/CSA Z271-10].

Continuous rail anchor

A continuous rail may generally be substituted for a series of separate anchors if it has been designed by a professional engineer for the intended purpose. It is also generally acceptable to tie both equipment tieback and lifelines to the rail or beam as long as each line is attached to a separate trolley, that the system is designed by a professional engineer for all loads likely to be applied (as if it were an extension of the roof structure), and that it is installed in accordance with the design.

Inspection records for building support structures

Every owner of a building where a suspended scaffold, boatswain's chair or similar single-point suspension equipment is to be used for window cleaning or where sill work is done shall cause all anchor points and permanently-installed suspended scaffolds to be inspected by a competent person in each of these situations:

- being used for the first time

- as often as necessary but not less frequently than recommended by the manufacturer of the anchor points or the suspended scaffolds, as the case may be

- in any case, at least once a year

- when informed of an inadequacy or defect [Regulation 859, sections 41(1) and 43)]

A building owner shall keep a record of the inspections of any anchor points and any permanently installed suspended scaffold at a building in a log book, to be maintained and retained as long as the anchor points and suspended scaffold are used, showing all of the following:

- the date on which each inspection is made

- the name and signature of the person making the inspection

- any modifications or repairs made to an anchor point or a suspended scaffold including the date they are made and the name and signature of the person making the modifications or repairs [Regulation 859, section 41 (4), (5)]

The CSA Z91-17 standard requires:

- inspection and testing of window cleaning suspension equipment which is permanently attached to the building, such as but not limited to, roof anchors and davits

- an engineer or a qualified person under the direction of an engineer to inspect and test the permanently installed equipment. [Section 8.2.1.1]

- a report to be generated by the engineer performing or overseeing the inspection and testing [Section 8.2.1.2]

- the report to be added to the permanent equipment log [Section 8.2.1.3]

Attachment on parapet walls

The employer must ensure that the parapet wall to which the parapet clamp or cornice hook is attached is engineered to withstand all loads likely to be applied to it. Generally, pre-cast concrete and cast-in-place concrete parapet walls designed as part of an original wall design are acceptable for installation of anchors for window cleaning purposes or the support of parapet wall clamps, provided the parapet wall is approved by a professional engineer who is aware of loads to be placed on the wall.

Location of anchors

Lifeline and tieback anchors should be located in line with the point of suspension whenever reasonably possible but should not be offset more than 3 metres (10 ft), measured horizontally from a line running at a right angle to the building face at the point of suspension. The angle created by the offset distance should not exceed 25 degrees [6.6.3.3.4 of CAN/CSA Z91-17].

Roof sketch

Every owner of a building where a suspended scaffold, boatswain's chair or similar single-point suspension equipment is to be used for window cleaning, shall prepare a sketch or sketches showing all anchor points and related structures on the building that are suitable and adequate for the attachment of the suspended scaffold, boatswain's chair or similar single-point suspension equipment and the lifeline [Regulation 859, section 39(1)].

As a minimum, the sketch should include, but not be limited to:

- a plan view showing essential structural members, including anchors and approach anchors

- details of the equipment and its installation

- the safe working loads of the equipment and any use restriction on the equipment

- all relevant obstruction and structures or other obstacles that impede the safe use or operation of the equipment

- the distance between anchors

- the location of all windows

- details of anchor system including, capacity, size and material used for every component

- related codes and standards used in designing the anchor system

The building owner must provide a copy of the sketch or sketches to the person supplying the window cleaning services before the work has begun. In addition, no employer may permit a worker to engage in window cleaning using a suspended scaffold, boatswain's chair or similar single-point suspension equipment until the employer has received a copy of the sketch or sketches [Regulation 859, section 39(2)].

The building owner shall post a copy of the above noted sketches near the entrance to the roof [Regulation 859, section 39(3)].

Davits

A davit located on the roof of building structure is piece of metal fitted into a wall or fixed to a post or pole, which may be used to support or hang scaffolding.

Davit bases

Generally, a davit base with an attachment point may be used as anchor for a life line or tie back if all of the following conditions are met:

- it is permanently attached to the structure

- for new installations, a letter signed and sealed by a professional engineer is provided stating that the main structure, the davit arm base and the method of connection between both are adequate to withstand all the applied loads

- the connection between the davit arm base and the main structure was performed in accordance with the Ontario Building Code and applicable regulations and is permanently attached

Permanent davits

Where an employer or building owner intends to rely on section 3 of Regulation 859 to use permanent davits, they must demonstrate that the use of permanent davits affords equal or greater protection to the health and safety than would otherwise be provided by complying with what is required by the Regulation. The employer or building owner should be able to show all of the following:

- it is designed according to good engineering practice

- it can be considered part of the structure

- it can withstand all loads that may be applied

Portable davits

Suspension equipment should be designed so that the maximum weight of any portable component does not exceed 70 kg. Consideration should be given to the ergonomics of handling and erecting the equipment with not more than two workers [CAN/CSA Z271-10 clause 7.2.1].

If there is a risk of portable equipment (davits and outriggers) falling over the edge of a roof during setup, then they should be secured by a safety cable or equivalent before installation, that should remain in place until the work has been completed [clause 6.5.6.6.3, CAN/CSA Z91-17].

Ropes/lines and lanyards

Static lines

Static or horizontal lines that are rigged between anchor points and to which lifelines or primary support lines are directly attached must be used as a professional engineer directs, and the professional engineer must certify the maximum load to be applied to the static or horizontal line [Regulation 859, section 29].

Lifelines

A lifeline used in a fall arrest system, shall, among other things:

- be suspended separately and independently from any suspended scaffold, boatswain's chair or similar single-point suspension equipment [Regulation 859, section 10(6)(c)], and

- be free from the danger of being chafed or cut [Regulation 859, section 10(6)(b)]

Every lifeline used in connection with a suspended scaffold that is permanently installed on a building or structure, a suspended scaffold that is transported in component form and is assembled for use at a work site, and a boatswain's chair or similar single-point suspension equipment intended for the support of one worker shall meet all of the following conditions, among other things:

- be rigged in accordance with generally accepted rigging practice

- be rigged so that each line hangs vertically from the roof or access level to the ground or level of egress of a worker using the line

- have a breaking strength of at least ten times the static load that the line is intended to support [Regulation 859, section 27(1)]

The lifeline rope should be of a type that is resistant to deterioration by chemical solutions used in operations and by exposure to atmospheric conditions of sunlight and moisture. All non-metal ropes that are not specifically designated as UV rated for exterior use should not be used [CAN/CSA Z91-17 clause 6.2.7].

The lifeline may be redirected from an anchor point to a davit arm [clause 6.3.6 of CAN/CSA Z91-17,] or a certified engineered device, providing that a letter from a professional engineer states the davit/arm device meets all of the following requirements:

- capable of resisting all arrest forces if a worker falls

- not used to support any suspension lines or other lifelines

- tied back to an anchor with an adequate steel sling

- arranged so that the worker cannot fall freely for a vertical distance of more than 1.5 metre

Where there is a risk of a lifeline slipping around the edge of a building, engineered rope stops/rope deflectors should be installed [CAN/CSA Z91-17, clause 6.3.3.8].

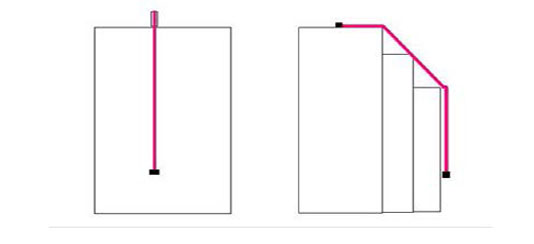

Suspension lines and lifelines which cannot be hung vertically due to building configuration

Section 27(1)(b) of Regulation 859 requires suspension lines and life lines to hang vertically from the access point to the ground. However, under section 3 of Regulation 859, an employer or building owner may vary the design or arrangement of any material, object, device or thing required by the regulation, provided the variation affords equal or greater protection to the health and safety of workers. Consequently, suspension lines and life lines may follow the profile of the building from the roof/or access level (see figure 1), as long as the arrangement affords equal or greater protection to the worker as if the lines were vertically hanging.

Figure 1

Examples of suspension lines or life lines following the profile of buildings from the roof.

The onus is on the employer/building owner to demonstrate that the varied method of protection meets or exceeds the protection that would otherwise be provided by complying with what is prescribed in the Regulation.

An inspector's determination of what may be considered acceptable under section 3 would be made on a case-by-case basis.

Where an employer or building owner intends to rely on section 3 to arrange the lines in a non-vertical configuration, to demonstrate that this varied arrangement affords equal or greater protection to the health and safety of workers than would otherwise be provided by complying with what is required by Regulation 859, an inspector would generally expect an employer to be able to show all of the following:

- a letter signed and stamped by a professional engineer stating that the arrangement of the lines in a non-vertical configuration affords equal or greater protection to the health and safety of workers

- that there is no potential of the worker swinging across the building

- that the lines are free from the danger of being cut or shaved at the point of redirection

- that the redirecting structure is capable of withstanding loads applied from a falling worker or a suspended scaffold

- that the added distance of redirection over another structure is taken into account to ensure that both the primary suspension lines and the lifeline are long enough to reach the landing or ground surface

Lanyards

A lanyard used in a fall arrest system shall have a nominal diameter of at least 16 millimetre and be made of nylon rope or another durable and adequate material. [Regulation 859, section 10(5)].

However, a shock absorber type lanyard (certified by CSA) is recommended as best practice and it should be as short as possible. It must also be compatible with the other components used in the fall protection system.

Communications

Every worker on a suspended scaffold, boatswain's chair or similar single-point suspension equipment shall have an effective means of summoning assistance in case of emergency [Regulation 859, section 31].

Generally, an effective means of summoning assistance is based on site-specific conditions where the means of summoning assistance can be easily heard and understood by a person from any part of the building. In some cases, a cell phone or other electronic device may be required for the safety of a worker.

Ergonomics: raising and lowering lines on buildings over 90 metres

Consideration should be given to the ergonomics of lifting electrical and suspension lines on buildings greater than 90 metres in height. Mechanical means should be used to raise or lower lines where the height exceeds 90 metres [clause 6.2.4 of CAN/CSA Z91-17]. Learn more about ergonomics in the workplace.

Employer work plan

Every employer who proposes to carry out window cleaning using a suspended scaffold, boatswain's chair or similar single-point suspension equipment or to carry out sill work shall prepare a work plan. Under section 42(1) of Regulation 859, the plan must meet all of the following requirements:

- be in writing

- be based on the roof sketch

- be signed by the employer

- indicate the manner in which any primary support lines and lifelines to use are to be attached to the anchor points or related structures shown on any sketches required by Regulation 859, Window Cleaning

- set out such other information required for the safety of workers

The work plan shall describe the intended work methods and necessary rigging procedures in accordance with the roof sketch. The work plan shall include all of the following, but not be limited to:

- the name of the building owner or contact person, including address and telephone number

- the name of the work site supervisor, including address and telephone number

- a general description of work

- the procedure for fall protection

- showing the tie in locations for the lifelines and the suspension lines for every window cleaning drop on the roof sketch

- the procedure for equipment rigging and usage of the manufacturer's operating and maintenance manual, included, but not limited to, the permanent and/or portable equipment rigging plans

- contact names and phone numbers in case of emergency

- emergency procedures, including but not limited to: worker injury, equipment damage/failure, and an emergency response plan

A copy of the work plan must be provided to each worker who engages in window cleaning or sill work at the building, with a copy retained for examination by an inspector [Regulation 859, section 42(2)].

No worker shall begin window cleaning that requires the use of a suspended scaffold, boatswain's chair or similar single-point suspension equipment and no worker may begin doing sill work until the worker has received a copy of the work plan [Regulation 859, section 42(3)].

Glass surfaces

Workers should not walk on or place any significant loads on any glass surface or frame, or both, in a skylight or atrium or canopy unless the glazing system has been engineered to safely permit this access method [clause 7.1.3 of CAN/CSA Z91].

Supervision

Every employer of a worker who engages in window cleaning using a suspended scaffold, boatswain's chair or similar single-point suspension equipment and every contractor and sub-contractor who proposes to carry out window cleaning in that manner must appoint a “competent person” as a supervisor [OHSA, clause 25(2)(c)].

Under the Occupational Health and Safety Act, a competent person is defined as a person who meets all of the following criteria:

- is qualified because of knowledge, training and experience to organize the work and its performance

- is familiar with this act and the regulations that apply to the work

- has knowledge of any potential or actual danger to health or safety in the workplace

The supervisor appointed for a window cleaning operation that uses a suspended scaffold, a boatswain’s chair, or similar single-point suspension equipment must visit the location of the window cleaning operation at least once daily [Regulation 859, section 44].

Training

For training requirement refer to subsection 9(2) and section 45 of Regulation 859. Employers should also refer to clause 3 of CAN/CSA Standard Z91-17.

Rope access and window cleaning

The rope access system

Rope access, if done properly, can be a safe work method where specialized techniques and procedures, relying on a system of ropes and related equipment, is used to access and perform work at height.

A rope access system permits the worker to safely move both vertically and horizontally to access the work location, which differs from other methods of accessing and working at height, such as a boatswain’s chair or a suspended scaffold.

Rope access uses a two-rope system that:

- employs a working rope/line and a safety rope/line for back-up fall protection should the main suspension line fail. In rope access, the safety line acts as the “lifeline” required by Regulation 859: Window Cleaning

- works in combination with a full body harness, lanyards, other devices such as anchors, ascenders, belay devices, back up devices and fall arrestors

- ensures each rope/line is always attached to separate and independent anchor points

Rope access is called a two-rope system because the working line and the safety line are interchangeable so that the working line may become the safety line, and vice versa, based on the rope access maneuver being performed by the rope access technician.

Rope access for window cleaning in Ontario

Use of rope access for window cleaning is not specifically addressed in Regulation 859. Some provisions of the regulation will apply to the use of a rope access system, whereas others will not. If an employer engages in window cleaning using a rope access system, it is that employer’s responsibility to ensure that it is done in compliance with the OHSA and applicable sections of the window cleaning regulation.

Provisions of the OHSA that will apply include, but are not limited to the following employer duties:

- clause 25(1)(b), the duty to ensure that the equipment, materials and protective devices provided are maintained in good condition

- clause 25(1)(e), the duty to ensure that a building, structure or any part thereof, or any other part of a workplace is capable of supporting any loads that may be applied to it

- clause 25(2)(a), the duty to provide information, instruction and supervision to a worker to protect the health or safety of the worker

- clause 25(2)(h), the duty to take every precaution reasonable in the circumstances for the protection of a worker

To comply with the OHSA and relevant provisions in Regulation 859, MLTSD recommends that employers using rope access for window cleaning refer to either the:

- International Rope Access Trade Association’s (IRATA) Code of Practice

- Society of Professional Rope Access Technicians’ (SPRAT) Safe Work Practices and Certification Requirements for Rope Access Work

Workers should be trained and certified to one of these standards and should be working in accordance with those standards.

Both associations maintain that successful rope access programs depend on all of the following four key components:

- management systems

- training systems

- equipment management systems

- qualified supervision

Training, certification and work practices other than those set out by IRATA or SPRAT may satisfy the requirements of the OHSA. In general, an employer relying on another source of training and certification should satisfy itself (and be prepared to demonstrate to an inspector) that the alternate training, certification and work practices are equal to or better than the IRATA or SPRAT training certifications and codes of safe practices.

The following information is provided to highlight some key areas of working with rope access systems to clean windows at heights and MLTSD expectations where the requirements of the regulation may not be applicable to rope access systems. Workplace parties are expected to be familiar with the Occupational Health and Safety Act and Regulation 859: Window Cleaning, and must comply with all applicable requirements.

Rope access instruction and training

In addition to an employer’s duty to take every precaution reasonable in the circumstances for the protection of a worker [clause 25(2)(h)], an employer must provide workers with information, instruction and supervision to protect the health and safety of the worker [OHSA, clause 25(2)(a)]. Every worker must be instructed and trained in the care and use of any protective clothing, equipment or device before the worker wears or uses it [Regulation 859, subsection 9(2)].

The Ministry recommends that employers of workers who will be involved in any aspect of rope access provide workers with the IRATA or SPRAT training program in the safe use of a rope access system. Employers should also provide workers with instruction on the rope access work plan and with any changes made to the plan.

Proof of training, such as certification documents provided by either IRATA or SPRAT, should be readily available on-site and produced at the request of a ministry inspector. Expired certificates will not be accepted.

Rope access system equipment requirements

Equipment should be certified to a recognized standard where applicable. This equipment includes:

- ropes

- climbing aids

- anchors

- connectors (which may also include lanyards and anchor slings for certain situations)

- snap hooks

- carabiners

- ascending and descending devices

- other rope clamping devices

The equipment must also be in good condition and should be used and inspected according to the manufacturer’s specifications.

Workers must wear or use personal protective equipment (PPE) that is suitable to protect them from the hazards to which the worker may be exposed [Regulation 859, subsection 9(1)].

Rope access equipment should be traceable to relevant test certificates including various international standards such as: CSA, CE, EN, ANSI, UL. Employers should track all rope access equipment history to ensure equipment is safe for use, or taken out of service, as needed. For example, fall arrest equipment used to arrest a fall must not be reused [Regulation 859, subsection 10(7)] and all equipment must be maintained in good condition [OHSA, clause 25(1)(b)].

In general, section 10 of Regulation 859 applies to rope access, however, there may be variances from requirements intended for traditional polypropylene ropes, such as the use of low-stretch 11 millimetre diameter kernmantle ropes which differ from traditional lifelines of at least 16 millimetre [Regulation 859, clause 10(6)(d)]. If an employer intends to vary from the composition, design, size or arrangement of anything prescribed by the regulation, it must ensure that the variation affords equal or greater protection to the health and safety of workers [Regulation 859, section 3].

The employer must ensure that workers wear a full body harness that is designed for rope access work as well as for fall arrest, while working at height using rope access.

Anchor system

The anchor system includes all of the following:

- anchors

- anchor lines

- anchorage (structural concrete or steel)

- anchorage connector (connecting device)

- anchor points

Permanent anchors should be used when available. As per CSA Z91-17 section 8.2.3.3, fixed roof anchors should be inspected or tested, or both, under the direction of an engineer. Testing should be performed at the interval specified by the anchor manufacturer or at an interval of 12 months, whichever is shorter, in conformity with the requirements of CAN/CSA-Z271. The results of the inspections should be documented and filed with the equipment log.

Employers must ensure that an anchorage to which a rope access system will be connected or secured is reliable and capable of safely withstanding any forces that may be applied to it [OHSA 25(1)(e)].

Rope access anchor systems that are planned, designed, installed, inspected, and used in accordance with either IRATA or SPRAT codes of practices are generally considered to be in compliance with general duties under the OHSA and applicable regulations.

Lines, ropes and connectors

Kernmantle lines/ropes should conform to standards recognized by IRATA or SPRAT for low stretch and static ropes, such as Cordage Institute (CI) standards including CI 2005 and CI 1801 which are specific to lines/ropes used for rope access. Kernmantle lines/ropes that are used, maintained, and inspected in accordance with IRATA or SPRAT standards and manufacturer’s specifications, would typically meet general duties under the OHSA and applicable sections of the window cleaning regulation.

Examples of rope safety include, but are not limited to the following:

- Adequate anchor line protection that will not dislodge during use, to protect the integrity and function of the rope (for example, protect both working line and safety line separately from damage from all potential hazards to the rope).

- Ropes are compatible with anchor line devices to be used (for example, descending, ascending and back up devices).

- Minimum static strength of ropes is 15 kN, tested in accordance with IRATA or SPRAT recognized standards including but not limited to CSA Z259.2.5, ANSI/ASSE Z359.15, EN 1891 and CI 1801.

- Ropes should be able to resist dirt and chemicals and perform in different environmental conditions.

On-site rope access work plan

Before any worker undertakes work with rope access, an employer should ensure that a written rope access work plan for the site has been developed by a competent Level 3 Technician in accordance with IRATA and SPRAT work practices prior to installation or use of a rope access system.

Employers should ensure that all rope access workers on the site have reviewed the rope access plan and have received instruction on the methods and procedures in the plan, before starting any rope access work [OHSA 25(2)(a),25(2)(h)].

Any modifications or deviations to the plan should be only done by the competent person. The competent person should review changes to the plan with the workers prior to any further work, and workers should receive the instruction necessary to perform the job safely.

The on-site rope access plan should contain at least the following:

- Name and location of the site.

- Name of the competent person who completed the plan and date of preparation of the plan.

- Name, proof of competency, (for example, rope access certificate number) and assigned duties of each worker on the rope access team.

- Hazards associated with the work to be performed for the site, including exposure to suspension trauma, electrical hazards, etc.

- Methods on how the hazards will be eliminated or controlled, including inspection of anchors, areas to protect from the public, etc.

- A list of personal protective equipment to be used by each worker.

- Detailed description of the rope access system, including equipment and devices, and how the system will be assembled, inspected, used, accessed, disassembled, and maintained.

- Description or drawing of anchors to be used, (for example, identify and describe each anchorage and anchorage connection system to be used) and procedures for providing security to anchor location.

- Detailed communication procedures.

- Emergency response, evacuation and on-site rescue procedures.

Electrical and other hazards

Electrical hazards may be present when workers are working near:

- electrical equipment

- power lines

- other energized electrical installation, equipment or conductors

Tools and other equipment that may conduct electricity and may endanger anyone’s safety shall not be used or left in proximity to energized sources [Regulation 859, section 33]. The regulation also provides for minimum distances of equipment from overhead electrical conductors [Regulation 859, section 35].

If practicable, a sufficient number of signs shall be posted in prominent locations to warn the public of window cleaning overhead [Regulation 859, section 12]. In addition, barriers, warning signs, or other safeguards shall be used to protect workers from vehicular or pedestrian traffic that may endanger workers or disturb the support lines or lifeline [Regulation 859, section 13].

Emergency and rescue procedures

The employer should ensure that adequate written emergency response, evacuation and on-site rescue procedures to rescue a worker specific to the given circumstances and location, is developed and ready for implementation. For example, the rope access plan may include procedures to be taken for electrical hazards or inclement weather that may cause hazardous conditions.

Emergency procedures account for all of the following:

- personnel

- equipment

- materials

- environmental factor controls

- self-rescue and immediate on-site rescue (specific to the site circumstances)

Equipment required to perform a rescue should be installed before any work is started.

Supervision

The supervisor should be Level 3 IRATA or Level 3 SPRAT certified and should be present at the rope access operation and in direct control of the rope access operation whenever workers are “on the ropes”.

Both IRATA and SPRAT standards have specific training and experience requirements for supervisors of workers who are involved in the rope access operation. According to SPRAT and IRATA standards, the rope access supervisors must hold a valid level 3 certification (issued by the respective organization).

Every person appointed as a supervisor must be competent in all aspects of rope access that apply to the work, including hazard identification and control necessary to ensure the health and safety of a worker.