Alert: Extending boom of an articulating crane while in stowed/travel position

Learn about the suggested precautions when working with articulating boom crane trucks.

Background

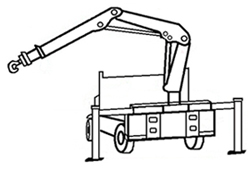

An articulating boom crane truck (“crane truck”), similar to that in Fig. 1, was brought into a mechanical garage to undergo repair of a hydraulic leak in an extension cylinder. The articulating boom, also known as a knuckle boom, was mounted at the back of a flatbed of a crane truck and had a lifting capacity of 6000 kg. The articulating boom consisted of an inner boom and an outer boom with a boom extension, which could extend out of, and retract into, the outer boom.

Fig. 1: Articulating boom crane truck

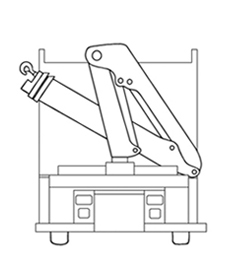

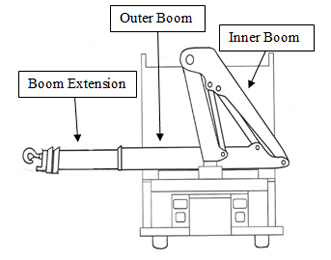

In order to verify that the leak had been repaired, a worker at the garage extended the boom extension out of the outer boom while the articulating boom was in the stowed / travel position (Fig. 2). This action caused the inner boom to come out of its rest position and move upward causing the outer boom and extension to suddenly drop approximately eight feet, due to a cantilever effect from the weight shift (Fig. 3).

Fig. 2: Before incident

Boom in normal stowed / travel position (with boom extension retracted)

Fig. 3: After incident

Position of outer boom and extension after dropping

A worker, working on a vehicle adjacent to the crane truck, was injured when the outer boom and boom extension dropped striking the worker on the side of the head and shoulder.

Hazard summary

The boom extension was extended while the articulating boom was still in its stowed / travel position (Fig. 2) which destabilized the articulating boom, causing the boom to come out of its stowed position and the outer boom and extension to drop onto the flatbed of the truck (Fig. 3).

The operator’s manual for this crane truck does instruct the operator on how to unfold the articulating boom crane prior to use; however, there is no notice in the manual or on the equipment that identifies or warns operators of the hazard that the boom arm can become destabilized and drop suddenly if the boom extension is extended while the articulating boom crane is in the stowed / travel position.

Locations and sectors

Crane trucks are primarily used to deliver material and equipment in the industrial and construction sectors. However, they can also be found in mechanical garages while undergoing maintenance and repair work where the potential to operate the crane in a manner similar to that of the above scenario may be more likely. This hazard alert addresses the safe handling and operation of the cranes while they are undergoing maintenance and repair work in a mechanical garage.

Precautions

Cranes with articulating booms should be operated in accordance with the manufacturer’s instructions and operating manual.

In addition, even if it is not stated in the manual, articulating boom cranes should always be unfolded (removed from the stowed position), prior to extending any of the boom extensions.

Employers must ensure that any worker operating a lifting device is competent or is a worker who is being instructed and accompanied by a competent person. Employers must ensure all operators, including shop mechanics that may operate the equipment for testing purposes, are provided with appropriate information, instruction and supervision. In addition, employers should ensure that workers operate the equipment as per the manufacturer’s operating manual, their training, and the employer’s safe operating policies and procedures.

Employers should ensure that workers stay clear of the danger zone around crane trucks and their loads at all times. No part of a load of a crane must ever pass over a worker. Employers must take any other precautions reasonable in the circumstances to protect the health and safety of their workers.

Applicable legislation

Clause 25(2)(a) of the Occupational Health and Safety Act states that,

…an employer shall,

(a) provide information, instruction and supervision to a worker to protect the health or safety of the worker.

Clause 25(2)(h) of the Occupational Health and Safety Act states that,

…an employer shall,

(h) take every precaution reasonable in the circumstances for the protection of a worker;

Clauses 51(2)(a) and 51(2)(b)(i) of Revised Regulations of Ontario 1990, Regulation 851 (the “Industrial Establishments Regulation”) state that,

A lifting device shall be operated,

51(2)(a) only by

- a competent person, or

- a worker being instructed who is accompanied by a competent person; and

(b) in such a way that,

- no part of the load passes over any worker…

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations, and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.